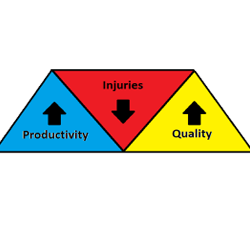

It is widely known and well accepted that ergonomics reduces workplace injuries/illnesses, improves process efficiency and lowers quality concerns.

A review of case studies was conducted from national conferences, OSHA publications, and RMG’s involvement to better understand companies’ impact with ergonomics. The following summarizes a sampling of ergonomic impact in three categories including Health & Safety Improvements, Operational Impact, and Quality Enhancements.

Health & Safety Improvements

Operational Impact

Quality Enhancements

Health & Safety Improvements

- TRW – Cookeville, TN – 83% reduction in WMSD rate

- Chevron Texaco – Multiple locations – 80% reduction in WMSD lost workdays

- Northrop Grumman – Sausalito, CA – 74% reduction in workers’ comp costs

- Owens Corning – Various locations – 34% reduction in WMSD incidence rates

- E. Dittmar – Zanesville, OH – 22% reduction in WMSD restricted workdays

Operational Impact

- WWL – Smyrna, TN – $697,000 increase in annual productivity

- Owens Corning – Multiple locations – 12% reduction in process downtime

- Toyota – Georgetown, KY – $94,000 reduction in annual labor costs

- Tamko – Knoxville, TN – 3% reduction of in non-value added walking

- Honda – Alliston, Ontario – 11% reduction in cycle time

Quality Enhancements

- Corning – Goose Creek, SC – $3.6 million reduction in quality issues

- Quaker – Danville, IL – averted $250,000 quality issue

- Nestle Water – Red Boiling Springs, TN – 3% improvement in fill consistency